Interviews

Keep Time the Low-Tech Way with The Self-Writing Clock

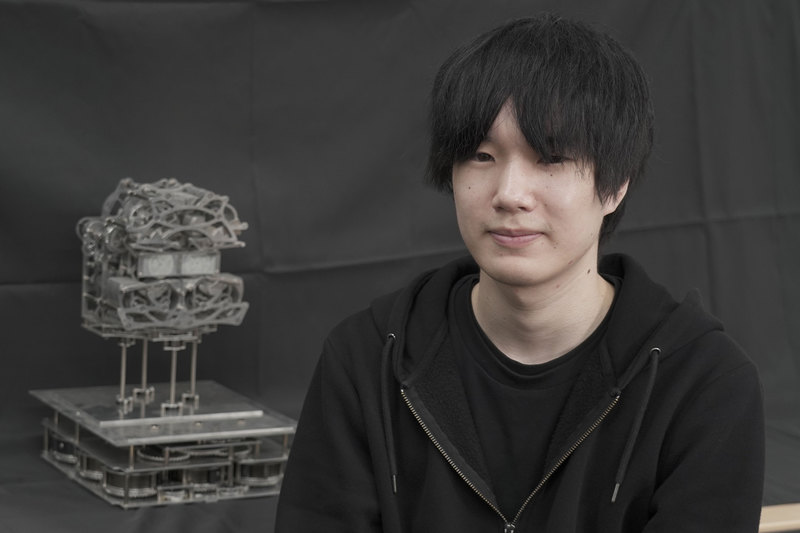

Kango Suzuki

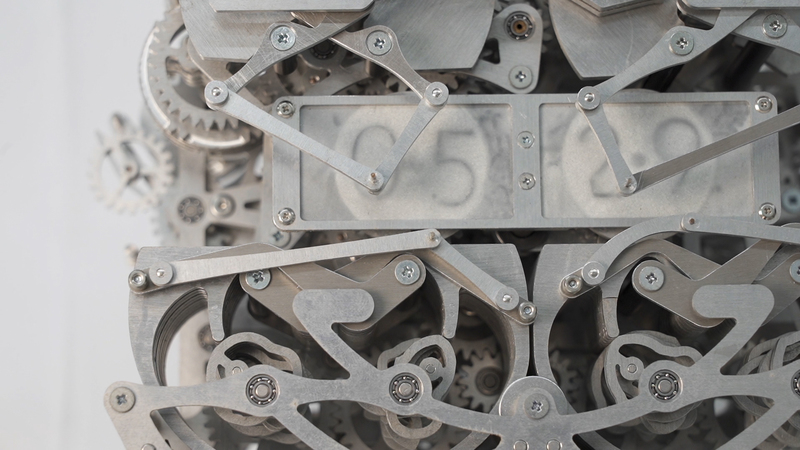

The Self-Writing Clock is a low- technology karakuri device that carefully writes down the time without using any digital processing.

Interviewer & Japanese Writer: Yamamoto Takaya; Translation & Editing: Matthew Cherry

Why did you decide to apply for the INNO-vation Program?

“I majored in product design in university, and as part of my major I was able to submit an art project as my graduation thesis, which is how I ended up making the Self-Writing Clock. The time on the clock is updated and written every minute by an arm that’s controlled by interlocking gears. I entered the INNO-vation Program because I wanted to make a smaller, more compact version than what I had already created.

The Self-Writing Clock that I made for my thesis was made of wood, so to make it smaller I needed a much more durable material to build with, so I chose duralumin. Cutting the wood on the first clock only required the use of a fretsaw, but in order to craft the gears and parts from duralumin I needed much more powerful machinery, and the materials themselves had a hefty cost as well. I wanted to take on the challenge of creating the smaller version by utilizing the support received from the program.”

How exactly did the development process go?

“First, I designed the model in CAD. It took a little time, however, because the development process wasn’t a case of simply reducing the size of the wooden clock.

With this version, the movement is controlled by a single power source that is diverted in two directions, one for the clock itself, and one for the arm to write the time. The movement that controls the writing mechanism has to stop moving intermittently, but the clock itself has to continually move. Diverting the power works to accommodate that, one direction that moves continuously, and one that stops every minute. Figuring out how to make that work was the most difficult part.

The original Self-Writing Clock consisted of over 400 parts, but the smaller version by comparison is made up of around 3,200 parts. There are even 30 different varieties of the gears themselves. Designing most of the gears took up a lot of time. I had planned on the design process to take about 2 months, but it ended up totaling around 3 months.”

After the design process, that’s when you put it together?

“First, the parts are cut out of the duralumin according to the CAD design by using a CNC milling cutter. Since there were so many parts to cut out, this was an incredibly time-consuming process.

Another thing I had to consider was that because the design in CAD had so many parts, my PC would freeze up whenever I tried to simulate movement. I had to look at the design while I was creating it to guess how it would end up potentially moving in the final product. When it came time to build it, I was checking each part’s movement as I was putting it together.

Putting together over 3,200 parts while painstakingly checking them all in this way took about 5 months to complete. The Disruptive Challenge lasts for a whole year, however, so I did end up with a lot of time remaining once it was complete.

The Self-Writing Clock does not use any digital mechanisms, it instead uses a 'karakuri' automata mechanic to control a pen that writes the time. 1,500 of its 3,200 parts are ready-made, while the other 1,700 were cut out using a CNC milling machine.

What are some things that could have gone better?

“The Self-Writing Clock uses a magnet-equipped arm to write the time every minute onto a magnetic board, but I encountered a problem where the arm would stop moving as soon as it began to write the time. Also, if the surface of any given part isn’t smooth enough, it’ll lose some force in that area. If the assembly itself is even the slightest bit off, the device loses force in those areas as well. I think the large number of moving parts contributed to an accumulation of errors, which in turn affected the final piece’s movement.

That being said, the design process and the assembly did go as planned. I was able to implement the writing mechanism as well as the cyclical erasing and re-writing of the time.”

What does the INNO-vation Program mean to you?

“I’m incredibly grateful to the INNO-vation Program. In the program, there’s not really a requirement to invent the latest cutting-edge technology. My Self-Writing Clock uses karakuri, and is a fairly low-technology device, but even creations such as these can be selected if the idea behind it is good. The idea itself is regarded as the important point of the challenge; actually achieving your goal isn’t a condition placed on your success. The program doesn’t take your past accomplishments into account, nor does it consider your experience with any particular machinery or industry. I encourage anyone with an idea they want to make a reality, even if it’s a little bit strange, to apply for the program.

Kango Suzuki’s Profile