Interviews

Capturing the Elegance of Organic Movement Through Animatronics (Part 1)

Akira Nakayasu

256 silicon tubes are the driving force behind the squiggling and squirming tentacles found in UNEUNEWARAWARA Animatronics. But how did its creator, Akira Nakayasu, come up with such an idea?

Interviewer & Japanese Writer: Yamamoto Takaya; Translation & Editing: Matthew Cherry

The title of this work, “Uneunewarawara Animatronics” (うねうねわらわら) comes from the combination of two Japanese onomatopoeia, “uneune/うねうね” meaning ‘winding’ and “warawara/わらわら” meaning ‘squirming’.

Akira Nakayasu’s UNEUNEWARAWARA Animatronics, selected for the 2016 INNO-vation Program’s Disruptive Challenge, is a mesmerizing work of art featuring 256 silicon tubes that squiggle and squirm thanks to its main driving force – 'BioMetal' actuators. All of these moving forces combine together to mimic the whimsical beauty of sea anemones swaying underneath the ocean waves.

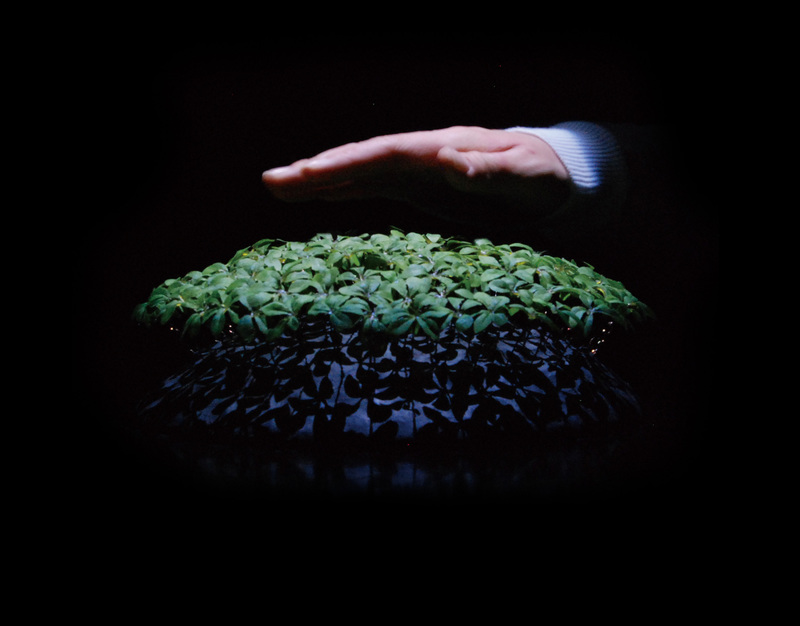

“It would be fascinating to have an accurate replication of a plant or organism’s natural movements without resorting to using CGI,” Nakayasu stated as the origin of his idea. In 2009, he created ‘plant’, an artwork conceptualized from the motif of grass rustling in the wind. With 169 artificial leaves that react to overhead hand gestures, ‘plant’ is an interactive piece that moves as gently as its real-life counterparts.

‘plant,’ a work from 2009.

In this piece, Nakayasu used Shape-Memory Alloy (SMA) together with actuators in order to replicate plant movement. In the beginning he attempted to use actuator motors, but he found that the movements they provided weren’t smooth and often resulted in clunky behavior that wasn’t lifelike. Another idea was to use several hundred pneumatic actuators instead, but they would have made the area of control too large and thus not intuitive to use.

“Organic lifeforms, such as plants, often move in a smooth, non-linear manner, but using motors resulted in really linear movements. The pneumatic actuators resulted in a control system that was too large, and the movements weren’t as precise as I had hoped they would be. I started to wonder what I could do to make the swaying more lifelike. After looking into various methods, I came across using Shape-Memory Alloy as a possibility,” Nakayasu recalled.

By heating conventional Shape-Memory Alloys, Nakayasu created his own unique material that fit with his original vision: a Shape-Memory Alloy that would gently bend in about 4 seconds.

With plant, Nakayasu took on recreating botanical life. Next, he set his sights on organic life. In 2010 he created Tentacles, which, much like plant used Shape-Memory Alloy actuators. As the name suggests, the piece consists of 55 individual tentacles that sway independently. Images taken by an infrared camera are converted into control signals, and when you wave your hand nearby, the tentacles start to move like anemones shimmering under the sea.

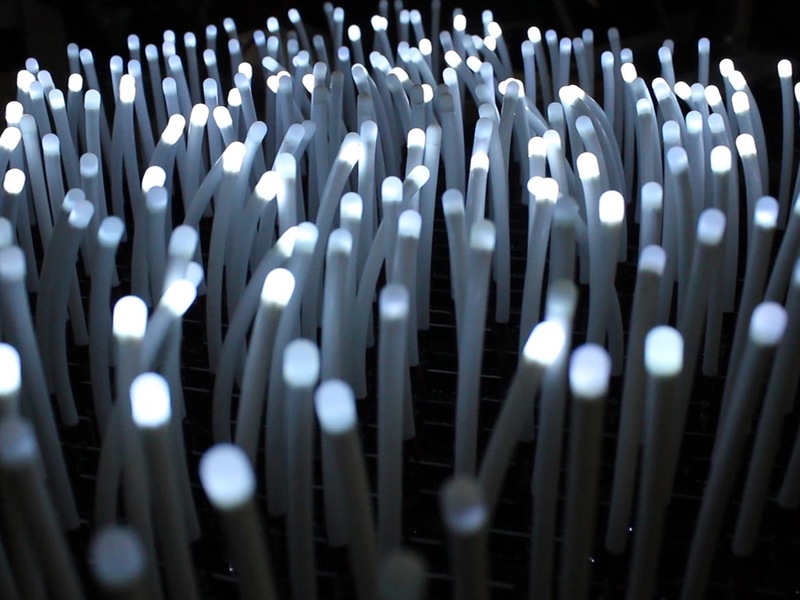

Continuing his development of Tentacles, Nakayasu completed Luminescent Tentacles in 2016. With this piece, an increased 256 tentacles were made from a special Shape-Memory Alloy BioMetal to record their length rather than their shape.

Luminescent Tentacles uses BioMetal material.

“The number of tentacles and their movement felt very natural, but Luminescent was still just a flat surface with tentacles attached to it, so it didn’t really feel like a true sea anemone. There was still a whole lot of room for improvement and progress, such as giving it a three-dimensional structure. I had already known about the INNO-vation Program for a while, so I decided to apply to try and get some support,” Nakayasu mentioned.

In part 2, we’ll ask Nakayasu about his development process during the INNO-vation Program.

Akira Nakayasu’s Profile